IMMEX Program Simplified

The Mexican IMMEX Program (Manufacturing, Maquila and Export Service Industry) is an instrument which allows companies to operate under a preferential tax and fiscal program. Foreign companies can transform and export goods or services temporarily brought to Mexico under this incentive program.

The IMMEX Program aims to enable foreign companies to produce goods or provide services from Mexico, in a way that is cost-effective while still focusing on quality. You may have heard of “maquiladoras”, and these are factories that import raw material into Mexico, use it in a production or transformation process (think machining, assembly, repair, etc) and then export it to their home country. The IMMEX Program is not only for physical goods. It also encompasses services in the knowledge transformation process. Think customer service, purchasing, design engineering or other corporate functions that can take place in Mexico.

With VAT Certification, these organizations can avoid paying value-added tax on these temporary imports that are destined for subsequent export. They can also temporarily import the raw materials and equipment used in the transformation process without the payment of VAT tax.

There are some requirements, of course. Companies in the IMMEX Program in Mexico have to export at least US$500,000 annually, or at least 10% of their total sales. They also must adopt certain inventory control systems, comply with time frames for the import and export of their goods or services, and operate in registered locations in Mexico, among others.

Read more about The IMMEX Framework here.

Importance of IMMEX

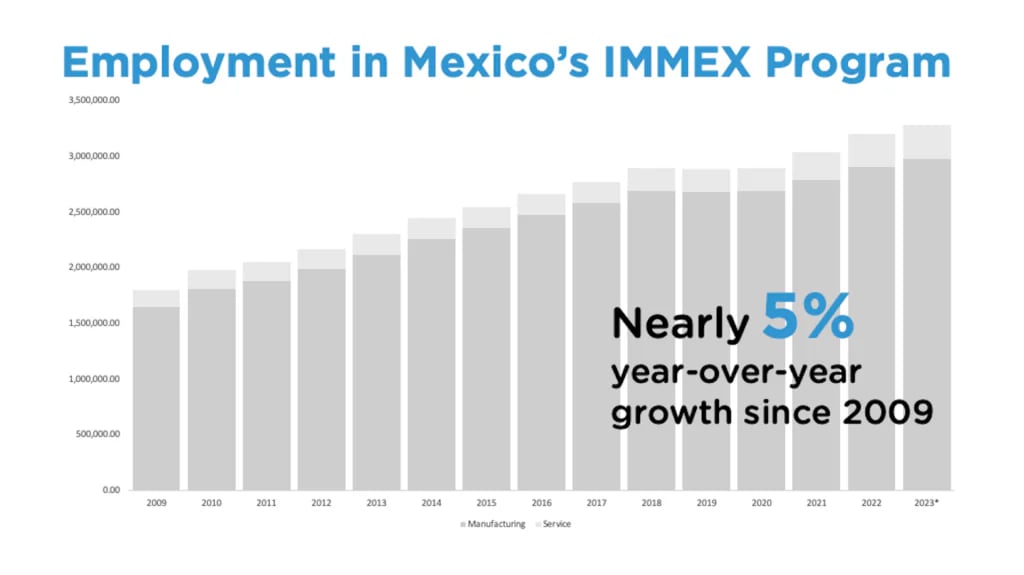

The IMMEX Program currently employs over 3 million workers in more than 5,000 certified operations throughout the country. Nearly 60% of IMMEX companies are located along the U.S.-Mexico border zone. About 35% of all manufacturing employees work in IMMEX companies.

IMMEX Employment in Mexico. Obtained by INEGI Jan 2024. *2023 data available up to October

The IMMEX sector in Mexico sets a tone for the manufacturing industry as a whole. Some of the most experienced and skilled talent is concentrated in IMMEX companies. The sector represents a lot of technology transfer to Mexico. Engineers, designers, and technical experts collaborate with their foreign counterparts on development, innovation and process improvement.

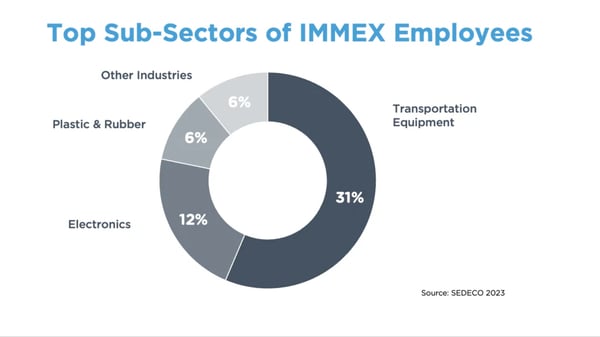

Four sub-sectors employ about 55% of all IMMEX employees in Mexico. Workers in IMMEX companies earn about 40% more than non-IMMEX companies.

Top IMMEX employment sectors. Source: SEDECO, 2023

The IMMEX industry is an indicator to the importance of the export sector in Mexico. Total exports in Mexico compose nearly half of the country’s GDP. Over 2016-2021, an average 55.8% of those exports and 43.3% of imports were driven by IMMEX companies.

About three quarters of Mexico’s exports go to the United States. In fact, half of all goods that are traded between Canada, the United States and Mexico are components used in local supply chains. Parts in an automobile assembled in Mexico may have crossed the border 7 or 8 times as it moved through different sub-assemblies. IMMEX companies have a great impact on Mexico’s economy.

Manufacturing in Mexico

Many global operations depend on Mexico as an essential gear in their global value chain. Mexico is a natural destination to provide manufacturing and administrative talent, especially for the U.S. market.

- Top bilingual talent trained in international systems and software

- Local time zones that facilitate real-time business communication

- Endorsement from global corporations continually expanding operations and shared services in Mexico

- Cultural similarities stemming from travel and technology transfer

As supply chain regionalize further through the process of nearshoring, manufacturing in Mexico will be increasingly important to the U.S. companies and their global operations.

“Nearshoring to Mexico is a reality today, that generates employment, economic development, social mobility and well-being for Mexicans. The degree of success will be determined by our ability to generate with great agility the conditions that allow us to take advantage of it to its full potential.”

– Emilio Cadena, CEO of Prodensa